Video(-Link) removed

We have deleted a demonstration video about the strength of the ceramic probes , which was earlier placed on a youtube- server by framing at this web pages.

Because this gives frictions with the new European General Data Protection Regulation (GDPR) and for protecting your identity at moment we can't link this.

We are looking for a other alternative solution.

Nevertheless you can watch the video by using this link:

https://youtu.be/_oCVL2rWd9M

(Copy +Paste to your Browser)

But keep in mind, that youtube-servers may track you!

4. Can the ceramic tube break?

In regular use - NO!

Using wrong fittings, mishandling, drop down or hit

with a massive part - perhaps but in installations in

reactors, vessels and pipelines the flanges are

designed with rugged deflectors (see Installations).

Some of the user work in higher viscosities which are

causing shear and bending loads.

But never crack such a load the ceramic tube.

See the small movie, that a force causing a shear

and bending load is not dangerous for the tubular

part.

In regular use - NO!

Using wrong fittings, mishandling, drop down or hit

with a massive part - perhaps but in installations in

reactors, vessels and pipelines the flanges are

designed with rugged deflectors (see Installations).

Some of the user work in higher viscosities which are

causing shear and bending loads.

But never crack such a load the ceramic tube.

See the small movie, that a force causing a shear

and bending load is not dangerous for the tubular

part.

2. Does ATR work in UV?

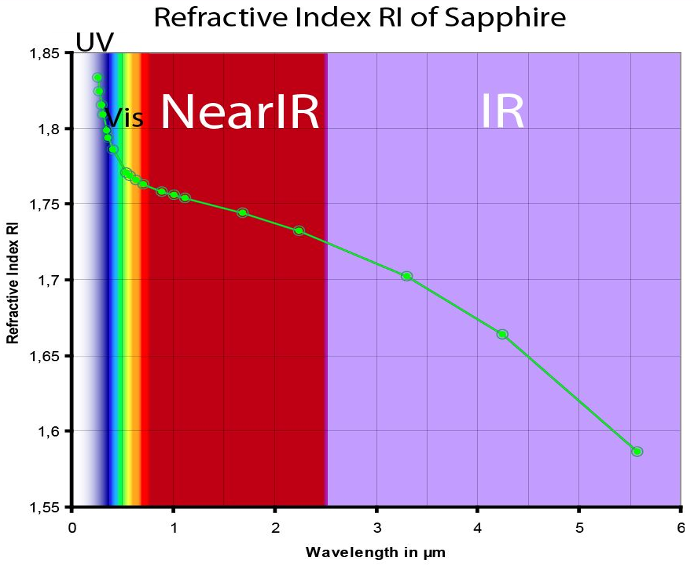

The Attenuated Total Reflectance technique (ATR) requires a certain refractive index(RI) relation to the sample material.

By the rapid increasing RI of Sapphire in UV the relation is in a well suitable range for a lot of organics and water based mixtures.

The Attenuated Total Reflectance technique (ATR) requires a certain refractive index(RI) relation to the sample material.

By the rapid increasing RI of Sapphire in UV the relation is in a well suitable range for a lot of organics and water based mixtures.

History:

* idea and first request 1990

* 1993 first probe with collimated beams

in Ø 12mm design like a pH-probe

(still metal made)

* December 1993 first probe prototypes

* 1994 first applications

* November 1995 production capabilty

* idea and first request 1990

* 1993 first probe with collimated beams

in Ø 12mm design like a pH-probe

(still metal made)

* December 1993 first probe prototypes

* 1994 first applications

* November 1995 production capabilty

Types of Probes

Achieved Rating

Installation

Spectrometers

Conductivity

FAQ

Imprint

Data

Protection

Protection

1. Why are the specifications limited between UV up to 2500 nm while Sapphire can transmit in Infrared up to 5000 nm?

Above 2500 nm the application in liquid process flows would require path length between 0,1 mm down to micrometer!

Such tiny transmission pathes (windows vis-a-vis) are in real process streams very critical because this narrow slits tend

to jam depending viscosity, pressure differences and inhomogeneities.

The known Attenuated Total Reflectance technique (ATR), used in Infrared for applying micrometer path length, is not

applicable between 2500 nm -5000 nm because of the fact, that the refractive index difference between most liquids

and Sapphire in the wavelength range is too small. See graphic!

Therefore probes made with Sapphire windows have in Near-Infrared transmission path length typical 0,5 mm -10 mm but

can expand to 50 mm and few more for low level tracing.

Above 2500 nm the application in liquid process flows would require path length between 0,1 mm down to micrometer!

Such tiny transmission pathes (windows vis-a-vis) are in real process streams very critical because this narrow slits tend

to jam depending viscosity, pressure differences and inhomogeneities.

The known Attenuated Total Reflectance technique (ATR), used in Infrared for applying micrometer path length, is not

applicable between 2500 nm -5000 nm because of the fact, that the refractive index difference between most liquids

and Sapphire in the wavelength range is too small. See graphic!

Therefore probes made with Sapphire windows have in Near-Infrared transmission path length typical 0,5 mm -10 mm but

can expand to 50 mm and few more for low level tracing.

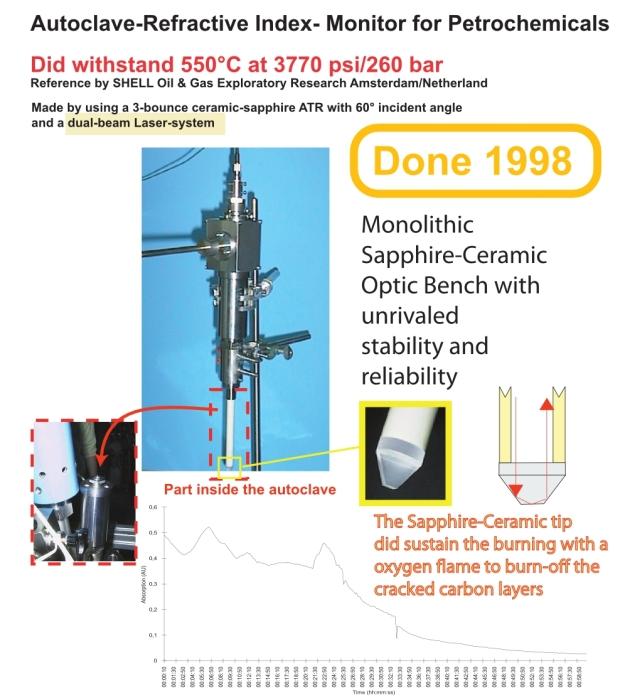

3. Is the ceramic probe durable and rugged enough?

Sure - some probes were/are working years in sticky batches!

Ceramic and Sapphire can withstand pressure and temperature better than every other material.

Some ceramics are used to cut stainless steel or to protect weaker materials.

In case of pressure and temperature from all sides no other probes system can demonstrate similar specifications!

Sure - some probes were/are working years in sticky batches!

Ceramic and Sapphire can withstand pressure and temperature better than every other material.

Some ceramics are used to cut stainless steel or to protect weaker materials.

In case of pressure and temperature from all sides no other probes system can demonstrate similar specifications!

Click for enlarging

!

Attention bending of the board at the load!